Broker Vs. Manufacturer – What’s the Difference?

Discussing the differences between a broker and manufacturer model for producing LED displays with Daktronics VP of design and development.

Justin Ochsner on 7/8/2020

Categories: Business & Community, High School Sports, Out of Home Advertising, Pro Sports and Colleges, Spectaculars, Transportation

Matt and I recently sat down with Brett Wendler, Daktronics Vice President of design and development, for a conversation on The Daktronics Experience podcast. Brett explained the differences between a manufacturing process and a broker process for LED technology and much more.

Justin: Here at Daktronics, we focus on developing large-scale LED systems, audio systems and control systems for all kinds of applications around the world. Can you explain how we conduct our business in the LED display industry?

Brett: As a company overall, we strive to have customers for life. What does that mean? As our customers are looking to add to their system, maybe they are looking to update their system or eventually replace their system with something new, we want to be the obvious choice. This overall fundamental concept of striving for customers for life is foundational for everything that we do and what we think about as we think about how we conduct our business. Then, we get into what we do to achieve that.

I would say, first and foremost, we start by truly making sure we understand what our customers value. How can we help them be successful to meet their objectives? With that understanding, we look for opportunities. How can we improve the value that we can provide to our customers? Not only for the display systems itself but also other products or services that might help our customers. Ultimately to ensure that our customers will have a system that will continue to work.

All that leads up to designing and delivering an LED display system. The details of this matter. An example is lifetime expectations of the display. I found so often people just assume that LEDs last 100,000 hours, or 10+ years. So, there is an assumption that all displays will last that long. LEDs are capable of lasting that long, but there are more factors involved to determine whether you are going to achieve that consistently.

So, as we talk to customers, we find that there are many examples where customers do value a product that lasts 10+ years, but there are also customers that would prefer a solution at a lower price and they are willing to accept a product that lasts 5+ years. So, understanding this can really influence our approach to design, how we select components for the system and even how we qualify the product to meet that type of expectation. That’s just one example.

Matt: Can you elaborate more on the differences between Daktronics’ approach as the display manufacturer versus a broker/distributor model?

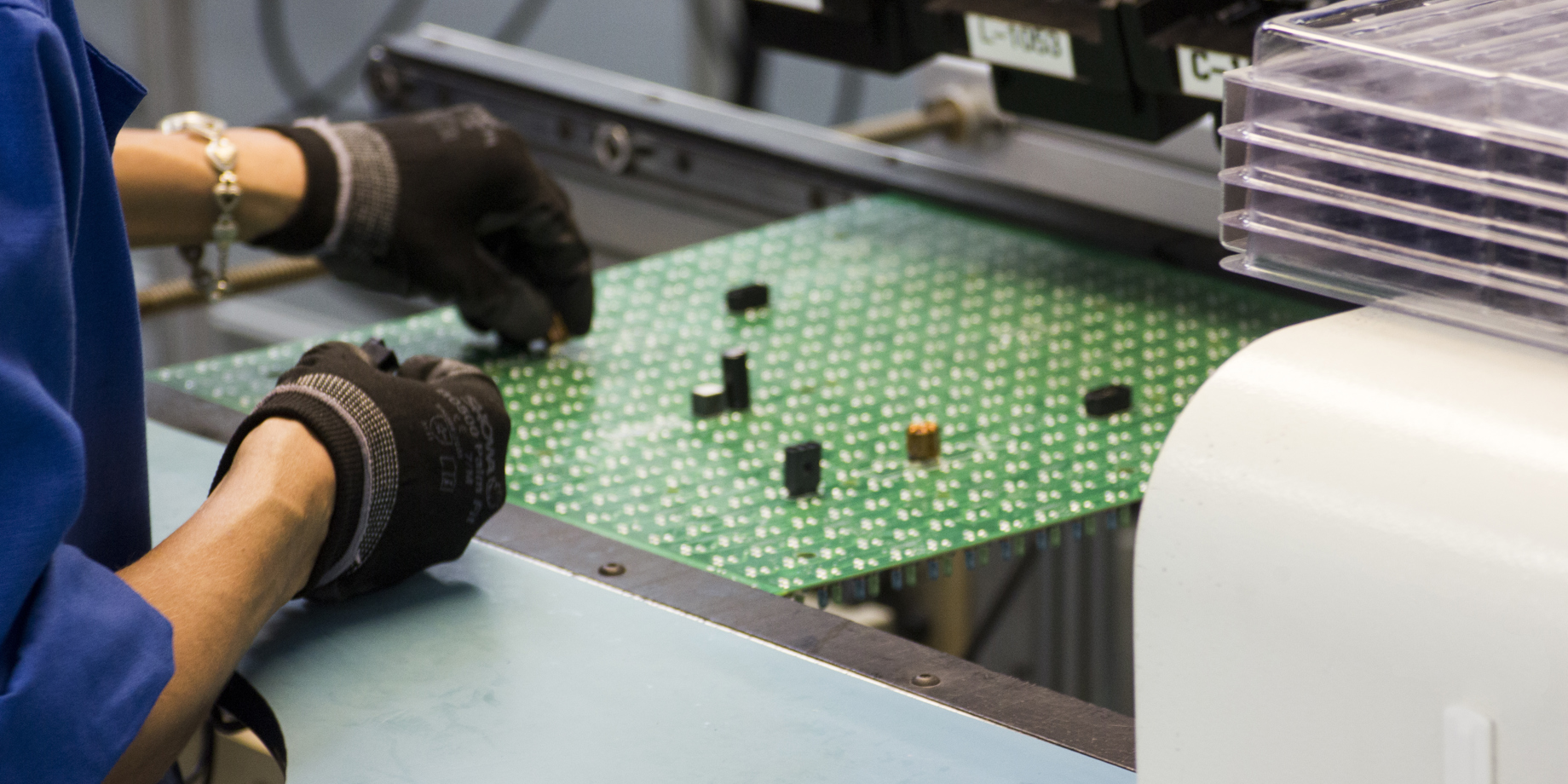

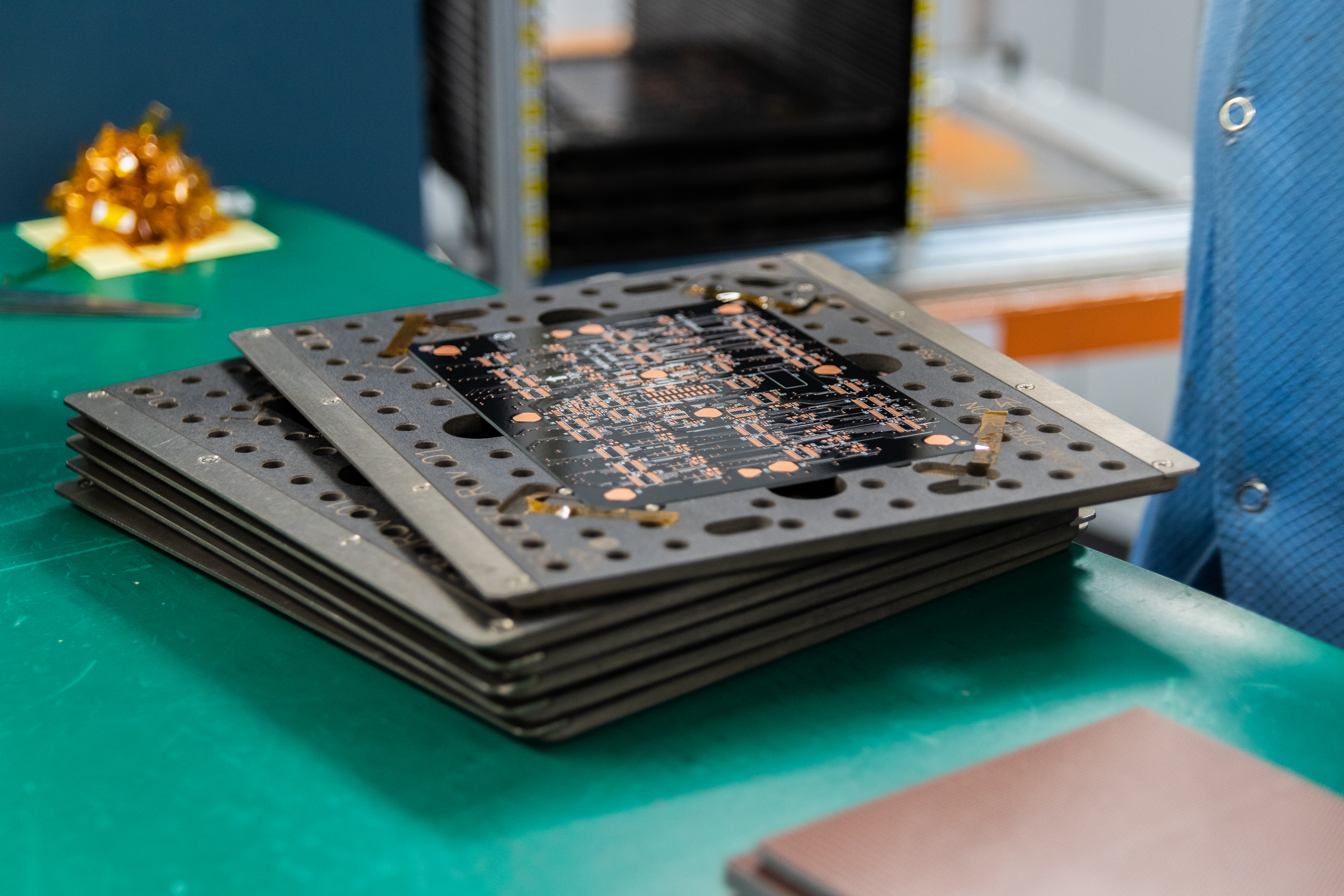

Brett: I’ll start by talking about the manufacturer perspective, which is how we approach things at Daktronics. We are purchasing components like LEDs, metal, screws and ribbons from suppliers to manufacture the product. We also design our own products, so we have the opportunity to be deep in the details and design choices at the component level. We can ensure that the components meet the performance requirements that our customers are asking for.

We view our suppliers as being responsible to consistently provide us with quality parts that meet the requirements that we have asked for. Then, it’s our responsibility to ensure that we are designing the right components for our system and taking those component choices and ensuring our manufacturing processes assemble them to come together and that they perform to meet expectations. We focus on working with companies that we can trust and we find benefit in these longer-term partnerships with these suppliers. We can improve together but also work together.

Justin: What does sourcing components look like for distributors or brokers?

Justin: What does sourcing components look like for distributors or brokers?

Brett: Looking at the distributor model, they really start at a point of disadvantage which is no fault of their own. Think about all the detail I talked about as a manufacturer in order to ensure that you are consistently meeting the customers’ requirements. A distributor is a whole step removed from all of that. So, they have another group of folks in the middle. Typically, a distributor is not buying LEDs, screws and metal. They are either buying the LED display system or maybe buying the key assembly like LED modules. Then they are putting it in a cabinet or a system together. So, it’s difficult for them to understand what the mindset of the engineer was when they designed that LED module, or what their philosophy and approach to sourcing components was. In most cases, a distributor doesn’t have the experience or might not even know the questions to ask a manufacturer because they are a step removed.

Matt: Can we dive in a little deeper into the manufacturing side of things? Can you talk a little bit about how all of this works with our process in Brookings, Sioux Falls and Redwood Falls?

Matt: Can we dive in a little deeper into the manufacturing side of things? Can you talk a little bit about how all of this works with our process in Brookings, Sioux Falls and Redwood Falls?

Brett: Our design engineering team works directly with our manufacturing engineers who are focused on our processes in the factory. The whole reason for that is to ensure that any design ideas that we have are compatible with manufacturing processes. Then, after we have released that product to market, as a manufacturer we have full control of changes that are made to the manufacturing process.

Justin: So, thinking about everything that goes into this process – sourcing, manufacturing and testing – how does this impact the customer directly?

Justin: So, thinking about everything that goes into this process – sourcing, manufacturing and testing – how does this impact the customer directly?

Brett: In the context of lifetime component sourcing, manufacturing processes, as well as the environment, all really influence how long the product is going to last. It turns out that we cannot really control the environment. That’s one of the things that we really need to understand. We can’t control the environment, but we can understand it. When we model based on the environmental conditions around the world, what are the targets we should be shooting for and testing as we set up our test plan and our test methods? That is a key factor for product lifetime of a display. A display that’s going to be in a harsher environment, like a hot, humid environment with a wide range of temperatures, it’s going to be more challenging for us. We don’t design to the best-case environment. We design toward the environment that this product is going to be used in. As a manufacturer, you are just in a better position because you manage the tests and the supply chain to bring it all together consistently to hit that product lifetime.

Justin: If something does happen with changes in the environment or something we can’t control, how do things look from the service and support aspect?

Brett: That’s something that many people don’t consider until they’ve had a bad experience. It’s exciting to have a system for the first time, but keeping it working and looking it’s best its entire lifecycle is also important. It’s not just how the display ages, it’s also important to know that you can get parts. Think about a distributor example. How much influence and control does the distributor have to get the parts you need to keep your system running? Often times people think the first year or two after install they can get the parts they need. The reality is that if you are in a situation where you are expecting ten years or more in performance from your system, getting the appropriate parts you need is quite a different challenge in year eight. Components from suppliers go obsolete and need to be replaced with new ones. Display manufacturers may want to move from one generation of product to the next. But you have to have a display installed and you still need parts for it. As a manufacturer who has a customer for life mentality, we keep this in mind and have a plan to support that.

Another example that some people might not think of is, what if you have an unexpected issue where the product is just not performing as you expected it? Maybe that issue happens within the first year. Who do you call? Who is going to take responsibility for that to make it right? As a manufacturer with the customer for life mentality, a customer can work directly with us and we will help you work through that.

To hear more about the broker vs. manufacturer processes for LED displays, check out the full conversation with Brett by clicking here.

*All pictures depict the level of components worked with during Daktronics’ manufacturing processes.